Building Technology Cornerstone

Building Technology Cornerstone

Building Technology Cornerstone

Building Technology Cornerstone

Writer:连接器屏蔽 Posted time {{1709549292000|timezoneDate({format:'YYYY-MM-DD HH:mm:ss'})}} views:155

Connector shielding refers to the protection of the transmission reliability of signals inside a connector by reducing or eliminating external electromagnetic interference (EMI) and radio frequency interference (RFI). Therefore, the shielding function of connectors is very important for fields such as telecommunications, computers, automobiles, industrial control, and medical equipment.

The shielding performance of a connector depends on various factors, including the design, materials, and manufacturing process of the connector. Common connector shielding techniques include:

1. Conductive coating

Conductive coating refers to applying a layer of conductive coating on the outside of a connector to form a shielding layer. This technology is easy to manufacture and use, and has a lower cost. Although conductive coatings can provide good shielding performance, they are difficult to cope with the interference of high-frequency signals.

2. Metal foil

Metal foil is a thin and soft metal sheet that can be attached to the inside or outside surface of a connector. Metal foil can provide good shielding performance and adapt to various designs and shapes. The disadvantage is that it is prone to wear and tear, and the shielding effect may be compromised in harsh environments or continuous use.

3. Metal mesh

Metal mesh is a metal material with a grid structure that can be used to manufacture the outer shell or inner shielding layer of connectors. Metal mesh can provide good shielding performance, and in some applications, it can provide good breathability and waterproof performance. The disadvantage is high manufacturing and assembly costs.

4. Metal shell

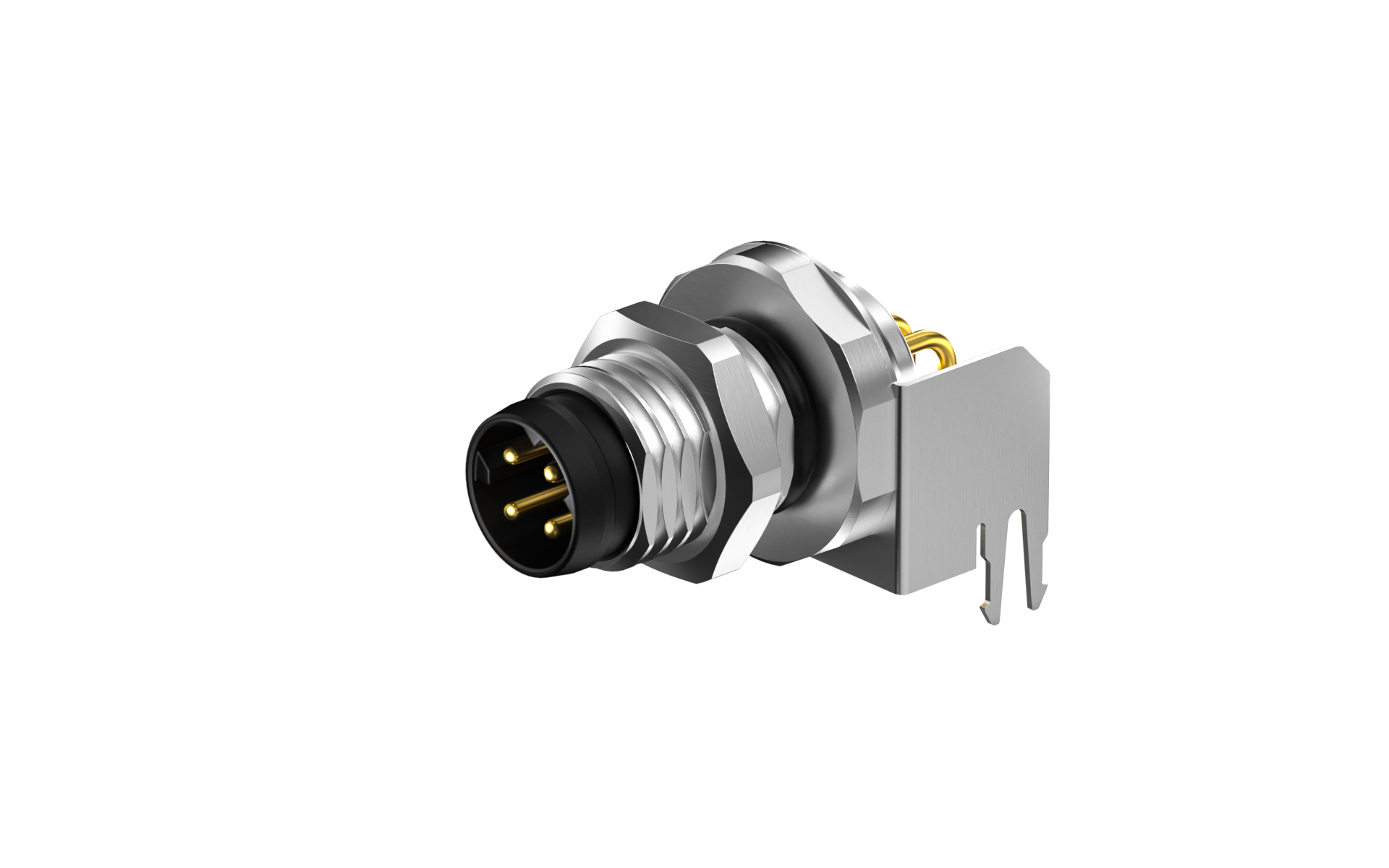

A metal shell is an integral metal shell that provides complete shielding for connectors and avoids external electromagnetic interference. But the disadvantage is that the cost is high, and the size and shape of the metal shell need to be considered in connector design and manufacturing.

TXGA is one of the leading domestic connector manufacturers with professional and mature production processes. You only need to propose the final application requirements and budget, and TXGA can provide a complete one-stop solution to assist your device research and development. Go to TXGA [Product Center] to learn more.