Building Technology Cornerstone

Building Technology Cornerstone

Please confirm your language, ship to and currency

Shipping options and costs will vary based on your ship to

Building Technology Cornerstone

Building Technology Cornerstone

Please confirm your language, ship to and currency

Shipping options and costs will vary based on your ship to

Industrial communication refers to various communication technologies and protocols used in industrial control systems to achieve data exchange and control signal transmission between industrial equipment. With the continuous improvement of industrial automation level, industrial communication has become one of the indispensable technologies in modern industry.

In this case, in response to the miniaturization and reliability requirements of industrial communication connectors, TXGA provides Mini l/O connectors with a volume of only 25% of RJ45. They support data transmission from 100Mbps (Cat5e) to 1000Mbps (Cat6A), have a plug and unplug life of 1500 times, comply with IEC 61076-3-122 standards, and have stable plug-in retention and anti-interference capabilities. They can provide compact, sturdy, and efficient connection solutions for industrial communication equipment in harsh environments such as electromagnetic interference and impact vibration.

Industrial robotic arm is an automatic device that imitates human hand movements, generally consisting of an actuator, a drive mechanism, a control system, and a machine base. By using connectors for electrical interconnection and driving, industrial robotic arms can perform operations such as grasping, handling, lifting, etc. according to the set program. In industrial production, the operational stability and execution accuracy of robotic arms are important factors that determine industrial production efficiency and safety.

In this case, TXGA provides a micro D-type connector for industrial robots with a contact spacing of only 1.27mm and a volume of only 50% of standard D-type connectors. It can provide more precise and lightweight circuit layouts for industrial robots, avoiding affecting their operational stability. The product adopts a twisted wire pin design, which has high anti vibration and anti impact capabilities to ensure stable data transmission of industrial robotic arms in harsh environments, providing more reliable guarantees for the stable operation and precise execution of robotic arms.

The drive system is an important component of industrial robots, generally composed of control units, drive circuits, and signal conditioning circuits. Through the drive system, industrial robots can convert electrical energy into mechanical energy, achieving various operations such as rotation, stretching, and lifting. In the field of industrial production, the robot drive system is the main factor determining the efficiency and stability of robot production.

In this case, TXGA provides a Micro match connector with a contact spacing of only 1.27mm for the industrial robot drive system, which can achieve a more precise circuit layout for the drive system. The cable connection method of the product adopts IDC puncture connection, and the wire end connector can be crimped and connected to the ribbon cable without the need for any additional tools or separate welding, forming a safe and reliable airtight connection between the connector and the ribbon cable, providing more guarantees for the electrical interconnection reliability of the industrial robot drive system.

Stacking robot is an automated device that can achieve efficient stacking of materials and integrated management of automated processes through technologies such as robotic arms, sensors, and computer control systems. Commonly used in industries such as logistics and manufacturing. While reducing labor intensity and ensuring safe material handling, it can also meet the application needs of special environments such as explosion-proof workshops.

In this case, the M16 (AISG) circular connector developed and produced by TXGA adopts a threaded locking structure, which can effectively reduce the risk of connector disconnection under impact vibration. The product is designed with a multi-layer sealed structure, supporting an underwater working environment of 50 meters. The connector housing is formed by alloy material die-casting, and the surface has undergone special process treatment to meet the salt spray test requirements of over 1000 hours. After locking the connector, it can lift a weight of over 15kg. Meet the electrical interconnection requirements of palletizing robots in harsh industrial environments.

Industrial control computers, also known as industrial control computers, are computers designed specifically for industrial settings. Through the bus structure, industrial control computers can detect and control the electromechanical equipment and process equipment in industrial production processes, which is the core of ensuring the normal operation of industrial equipment. At present, industrial control computers have been widely used in control places, road and bridge toll collection, medical treatment, environmental protection, intelligent transportation, communication, monitoring, CNC machine tools, finance and many other fields.

The DVI connector developed and produced by TXGA is a high-definition image transmission solution in a harsh industrial environment.In view of the demand for high-definition image transmission of industrial computers in the industrial vibration environment, the maximum refresh rate of the DVI-I connector developed and produced by TXGA is 120Hz. At the same time, the two sides of the product are equipped with screw locking structures, which can keep the connectors firmly interconnected. It can achieve smooth and clear picture effect for industrial personal computer under severe vibration environment.

Industrial automation control refers to the use of computer technology, microelectronic technology, and electrical means to make the production and manufacturing processes of factories more automated, efficient, precise, and controllable and visible.As an important control device in the field of industrial automation, the industrial core controller is a professional computer specially designed for industrial production control. It can monitor and control machinery and equipment, production processes, and data parameters in the industrial production process to ensure industrial production Smooth operation on site.

The Gigabit Ethernet port provided by TXGA for the industrial core controller adopts a superimposed design, which can realize a more compact circuit arrangement design in the device. The product conforms to the Ethernet IEEE802.3 standard, with reliable communication, flexible arrangement and strong anti-interference ability. And there are products with and without lights to choose from, to meet the application needs of embedded industrial control systems.

The robotic arm is the most widely used automated mechanical device in the field of industrial robot technology. It can be seen in fields such as industrial manufacturing, medical treatment, entertainment clothing, and semiconductor manufacturing. Compared to general robots, robotic arms condense all motion modes into three types - stretching, rotating, and lifting, greatly reducing development difficulty and production costs.

In this case, txga provides a series of suitable connector products for industrial manipulator, including harness, wire to board connector, pin and bus bar, USB connector, etc. The product supports high voltage and high current transmission, can work in extreme high and low temperature environment, and has superior environmental performance. At the same time, it has good vibration resistance, impact resistance and protection performance to meet the application requirements of industrial production environment. Our connector products also realize miniaturization and lightweight as much as possible to meet the wiring requirements of the space in the manipulator.

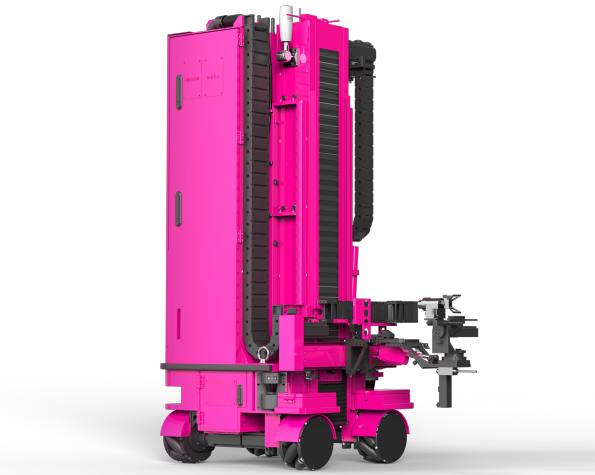

Robot is an intelligent machine that can work semi autonomously or fully autonomously. It has the basic functions of perception, decision-making and execution. It can assist or even replace human beings to complete dangerous, heavy and complex work, improve work efficiency and quality, and serve human life. In the construction industry, robots in related processes have appeared in the processes of measurement, floor cleaning, ground leveling, ground troweling, basement troweling, ceiling polishing, indoor spraying, garage spraying, etc., providing new solutions to the problems of labor shortage, high safety risk, slow construction speed, unstable construction precision and so on.

In this case, txga brings high-performance and durable solutions and high-quality connector products to construction robots. The wire to board connector products used are waterproof and dustproof, impact and vibration resistant, adapt to long-time operation, and are not afraid of construction challenges such as dust and dirt. Meet the application requirements of high strength and miniaturization.

Handling robots are one of the most important equipment in the modern warehousing system. It can efficiently, accurately and flexibly complete the handling of basic materials and realize automatic handling operations. At present, it has been widely used in various scenarios such as machine tool loading and unloading, automatic production lines of stamping machines, automatic assembly lines, palletizing and handling, and containers. Because handling operations are often carried out indoors, handling robots widely use electric energy as a driving energy and use charging piles to charge.

The charging pile module power connector and high-current D-SUB connector series products provided by TXGA for industrial handling robot charging piles have outstanding high-current transmission capability and safer heat-resistant and flame-retardant design. It can effectively improve the charging efficiency of industrial charging piles, meet the needs of fast charging and safe charging of industrial handling robots, and escort modern smart factories.