Building Technology Cornerstone

Building Technology Cornerstone

Please confirm your language, ship to and currency

Shipping options and costs will vary based on your ship to

Building Technology Cornerstone

Building Technology Cornerstone

Please confirm your language, ship to and currency

Shipping options and costs will vary based on your ship to

Writer:连接器 Posted time {{1760166997000|timezoneDate({format:'YYYY-MM-DD HH:mm:ss'})}} views:27

Surface mount and through-hole soldering are two mainstream installation methods in the field of connectors.

Surface mount refers to placing connectors directly on the surface of a PCB board (printed circuit board) and achieving electrical and mechanical connections with the PCB board using solder. Through hole soldering is to first insert the pins of the connector into the through holes of the PCB board, and then connect them through methods such as wave soldering.

From the perspective of installation efficiency, surface mount technology usually has high installation efficiency due to the use of automated equipment for mounting and welding, and can achieve high-speed and high-precision production goals. Although through-hole welding can also achieve automation, the plug-in process is relatively cumbersome and the production efficiency is relatively low.

In terms of applicability, surface mount connectors are suitable for small, high-density, and highly integrated electronic devices, and are widely used in the field of consumer electronics, such as smartphones, computers, tablets, etc. Through hole welding connectors are more suitable for larger, heavier, and more reliable equipment, such as power modules, relays, etc., commonly found in industries such as industrial control and medical equipment.

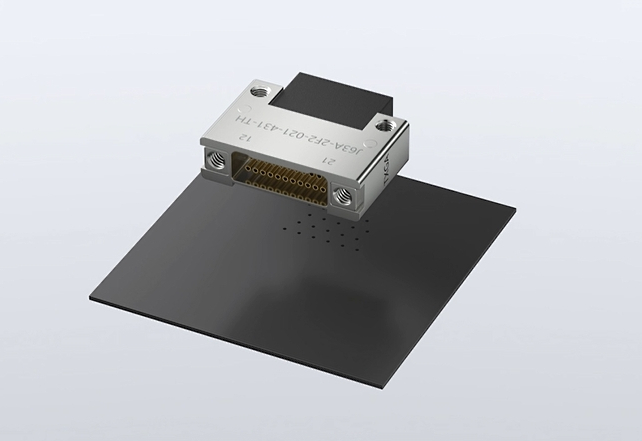

Surface mount image:

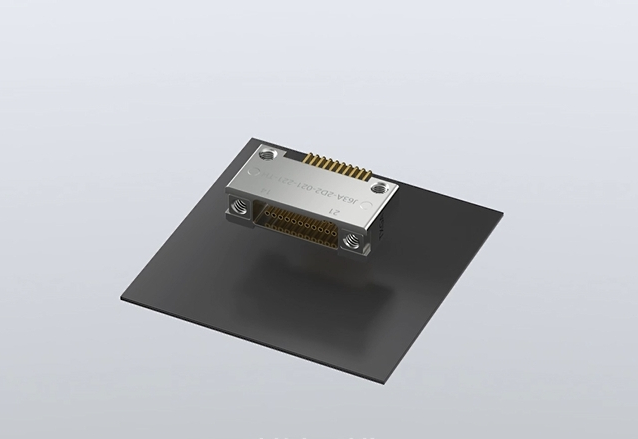

Picture of through-hole welding: