Building Technology Cornerstone

Building Technology Cornerstone

Building Technology Cornerstone

Building Technology Cornerstone

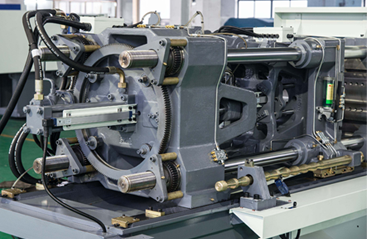

TXGA has established an injection molding workshop to serve the production of connector/connecting wire products and provide molding injection assistance for customized parts

TXGA Purchasing Department establishes special raw material supplier management

The selected raw materials meet many regulations such as industry standards, RoHS environmental protection standards, UL certification, etc.

Assist R&D and design to complete product development

Not open to the outside world, specifically for TXGA custom molding injection molding

Establish a 100 square meter production workshop

Introduce advanced production equipment to serve production

The average industry experience of injection molding engineers is more than 6 years, some up to 10-15 years

The R&D department collaborates in production to optimize the production process

TXGA relies on the ERP system to establish a complete production process. Responsibility to people

Independent processing of injection molding, eliminating third-party communication and shortening the production cycle time

R&D department and quality department cooperate to control product quality throughout the process

R&D department and quality department cooperate to control product quality throughout the process