Building Technology Cornerstone

Building Technology Cornerstone

Please confirm your language, ship to and currency

Shipping options and costs will vary based on your ship to

Building Technology Cornerstone

Building Technology Cornerstone

Please confirm your language, ship to and currency

Shipping options and costs will vary based on your ship to

Writer:Micro Match连接器 Posted time {{1694772769000|timezoneDate({format:'YYYY-MM-DD HH:mm:ss'})}} views:74

Electronic devices are often affected by mechanical forces such as impacts and vibrations during transportation and operation. Among them, the continuous vibration of the equipment can easily cause mutual wear and tear between the male and female terminals of the connector, forming frictional corrosion and affecting the service life of the connector.

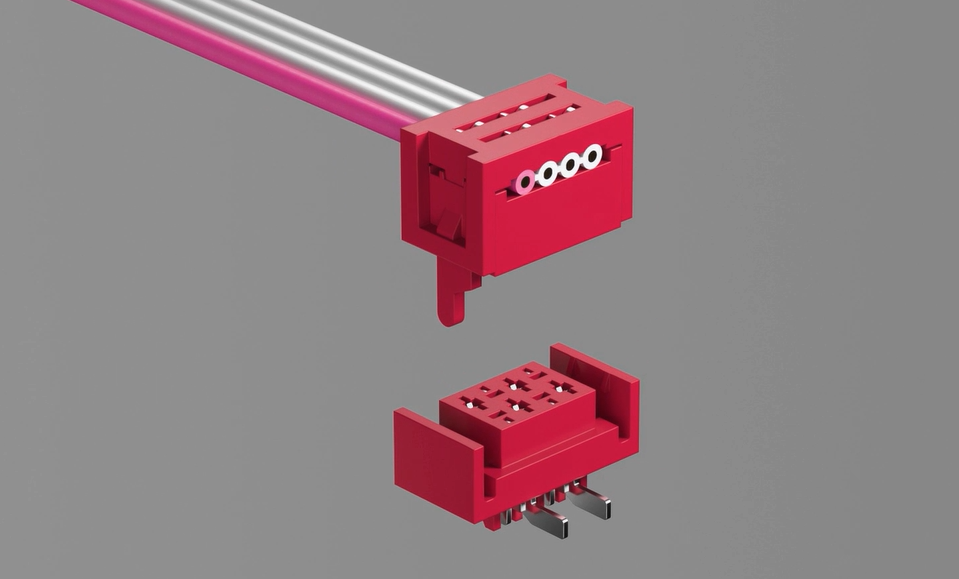

TXGA Micro Match connector with elastic contact design for terminals. After insertion, the elastic structure of the terminal can buffer environmental vibration, maintain relative fixation between male and female contacts, effectively reduce friction and corrosion of the contacts caused by pin vibration, and provide stable and reliable electrical connections for electronic devices in harsh vibration environments.

performance parameter

Maximum current per contact 2A

Voltage - maximum 250V

Contact resistance 20 m Ω Max

Insulation resistance 1000 M Ω Min

Product advantages

Contact spacing is only 1.27mm, suitable for compact equipment

The cable connection method adopts IDC puncture connection, making installation more convenient

The contacts are designed with an elastic structure, effectively preventing friction and corrosion

The product can operate in environments ranging from -40 º C to+105 º C

Specification and model

Line end plugs are available in models such as 4-core, 6-core, 8-core, 12-core, and 18-core.

Board end sockets are available in models such as 4-core, 8-core, 10-core, and 16-core.

Industry applications

The Micro Match connectors developed and produced by TXGA have been widely used in fields such as automotive electronics, industrial robots, temperature and humidity controllers, and data communication.